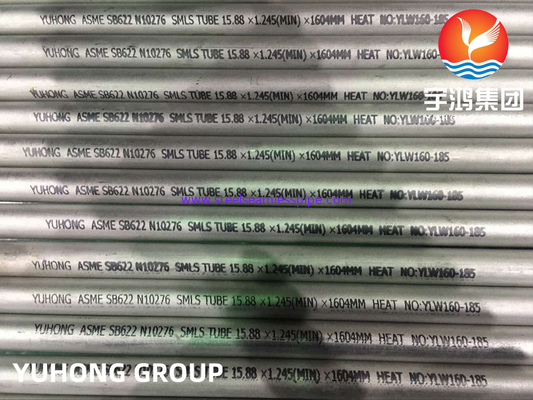

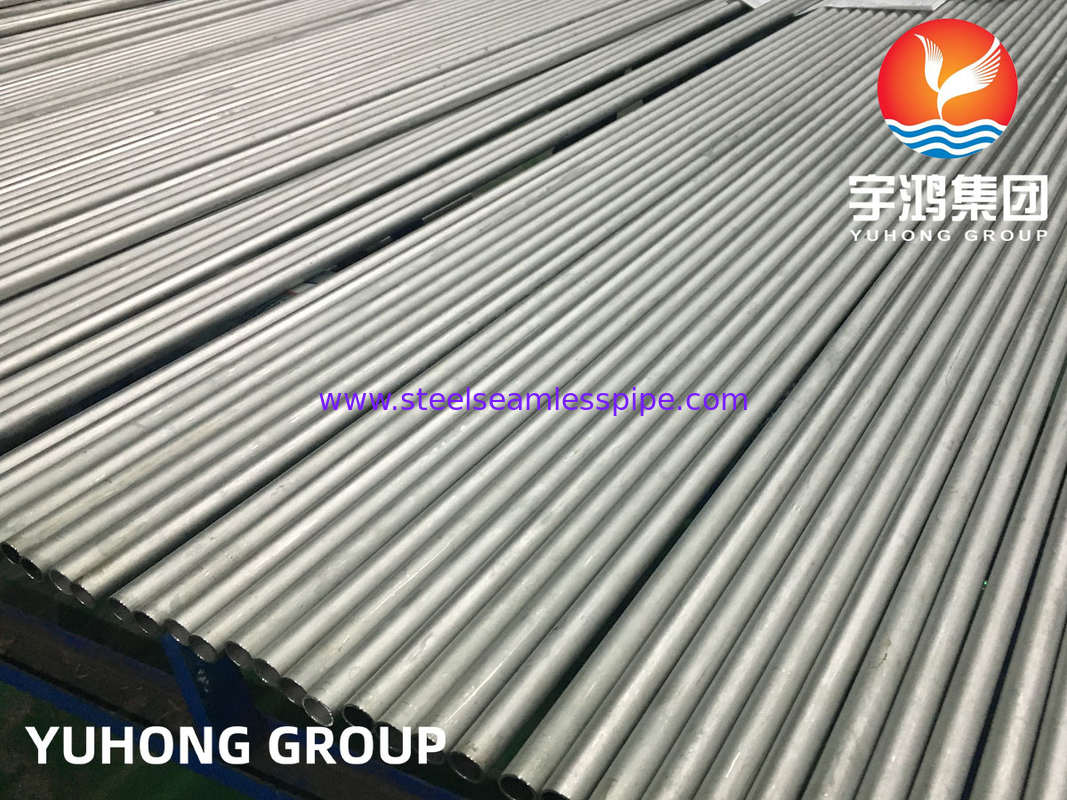

Yuhong Holding Group Co.,LTD

English

-

English

-

French

-

German

-

Italian

-

Russian

-

Spanish

-

Portuguese

-

Dutch

-

Greek

-

Japanese

-

Korean

-

Arabic

-

Hindi

-

Turkish

-

Indonesian

-

Vietnamese

-

Thai

-

Bengali

-

Persian

-

Polish